Put your alternative Non Flash content here.

Silicone Rubber

"An excellent material for enhanced fire protection solutions in railway industry

Fire Safety In Industry

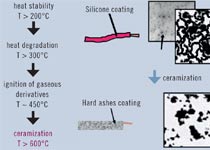

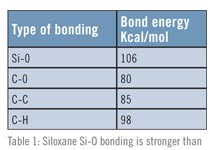

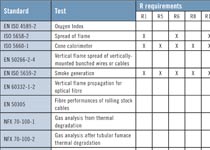

The fire behaviour improvement of products forms a major research axis in several industries as transportation, cable, composite insulators. On this base, it is now possible to propose rubber technical parts (profiles, gaskets, cables, O ring, bellows…) which can offer better safety for people and goods by lowering fire propagation, but also collateral effects like smoke opacity and gas toxicity. The most commonly identified cause of death from a fire incident is being overcome by gas or smoke which accounts for 44% of all deaths 1. Another influential source, the Swedish SRSA (Swedish Rescue Services Agency) in a report on Fire Prevention states that: “In 1950 the average time from ignition of a fire to flashover was 15 minutes. Then, 25 years ago, that time was down to 5 minutes and now fatal conditions can occur after 3 minutes. This change has come about because of the increase of plastics in our homes, nothing else 2. Fires have also a significant impact on our economy. In a recent report, CTIF (International Association of Fire and Rescue Service) estimates that: “The total economic costs of fires amount to around 1% of gross domestic product in most advanced countries 3“. Given these facts, conclusions are: • The reduction of smoke and effluent gases is relevant to saving human lives and facilitating the work of rescue teams, • Increasing use of plastics in the last 50 years has had a dramatic effect on escape times. This situation put in evidence the necessity to offer enhanced fire protection solutions. In this field, silicone rubber (SR) is an appropriate material with many advantages. From a general point of view, all kinds of SR (heat cure rubbers HCR, liquid silicone rubbers LSR, room temperature vulcanizating RTV-1/ RTV-2) share many similar criteria. Their formulations are based on Polydimethylsiloxane polymers (PDMS) which bring the basic characteristics of silicones: • Thermal stability in a wide range of temperatures (-50°C up to + 300°C) • Outstanding resistance to weathering, O2, ozone, UV, polluted areas • Excellent fire resistance (low smoke emission / non toxicity and non corrosive smokes) • Excellent dielectric properties with high electrical insulation performances • Water repellency